The Advantages and Applications of Tinned Copper Power Cables

Introduction

Tinned copper power cables are a type of electrical cable that is widely used in various industries for transmitting power efficiently and safely. These cables are made of copper conductors that have been coated with a thin layer of tin, which offers several advantages over traditional copper cables. In this article, we will explore the benefits and applications of tinned copper power cables in detail.

1. What are Tinned Copper Power Cables?

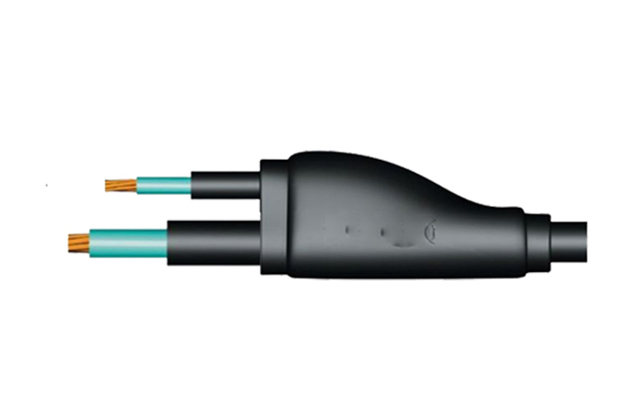

Tinned copper power cables are electrical cables that consist of copper conductors with a layer of tin coating applied to them. The tin coating is typically applied through a process called electroplating, which involves immersing the copper conductor in a solution containing tin ions and applying an electrical current to deposit the tin onto the surface of the copper. This results in a thin, uniform layer of tin coating on the copper conductor.

Mineral Insulated Cable serves several important purposes in tinned copper power cables. Firstly, it provides a protective barrier against corrosion, which can occur when copper is exposed to moisture and other environmental factors. The tin coating prevents the copper from oxidizing, ensuring that the cable remains conductive and reliable over its lifespan.

Additionally, the tin coating on tinned copper power cables improves their solderability, making it easier to connect and terminate the cables during installation. The tin coating also enhances the flexibility of the copper conductors, making the cables easier to bend and route in tight spaces without damaging the conductors.

2. Advantages of Tinned Copper Power Cables

Tinned copper power cables offer several advantages over traditional copper cables, making them a popular choice for a wide range of applications. Some of the key advantages of tinned copper power cables include:

2.1 Corrosion Resistance: One of the primary advantages of tinned copper power cables is their excellent corrosion resistance. The tin coating acts as a barrier that protects the underlying copper conductor from moisture, chemicals, and other corrosive agents, ensuring that the cable maintains its performance and reliability in harsh environments.

2.2 Solderability: The tin coating on tinned copper power cables improves their solderability, making it easier to create secure and reliable connections between cables and electrical components. This is particularly important in applications where reliable electrical connections are critical, such as in industrial machinery and power distribution systems.

2.3 Flexibility: The tin coating on tinned copper power cables enhances the flexibility of the copper conductors, allowing the cables to be bent and routed more easily without risk of damage. This flexibility is especially beneficial in applications where space is limited, as it allows for easier installation and maintenance of the cables.

2.4 Longevity: Tinned copper power cables are known for their longevity and durability. The tin coating helps to protect the copper conductors from wear and tear, extending the lifespan of the cables and reducing the need for frequent replacements. This makes tinned copper power cables a cost-effective choice for long-term installations.

2.5 Electrical Performance: Tinned copper power cables offer excellent electrical performance, with low resistance and high conductivity. The tin coating helps to maintain a consistent electrical connection, reducing the risk of signal loss or interference in power transmission applications.

3. Applications of Tinned Copper Power Cables

Tinned copper power cables are used in a wide range of applications across various industries due to their numerous benefits and superior performance characteristics. Some of the common applications of tinned copper power cables include:

3.1 Automotive Industry: Tinned copper power cables are commonly used in the automotive industry for wiring harnesses, battery cables, and other electrical components. The corrosion resistance and durability of tinned copper cables make them ideal for use in vehicles, where exposure to moisture, heat, and vibration is common.

3.2 Marine Industry: Tinned copper power cables are also widely used in the marine industry for wiring systems on boats, ships, and offshore platforms. The corrosion resistance of tinned copper cables makes them well-suited for marine environments, where exposure to saltwater and humidity can cause rapid deterioration of traditional copper cables.

3.3 Renewable Energy Systems: Tinned copper power cables are essential components in renewable energy systems, such as solar panels and wind turbines. These cables are used to transmit power from the renewable energy source to the electrical grid, providing a reliable and efficient connection that maximizes energy output.

3.4 Industrial Machinery: Tinned copper power cables are commonly used in industrial machinery and equipment, where reliable power transmission is critical for operation. The corrosion resistance and flexibility of tinned copper cables make them well-suited for use in harsh industrial environments, where exposure to dust, moisture, and chemicals is common.

3.5 Data Centers: Tinned copper power cables are also utilized in data centers for power distribution and backup systems. The excellent electrical performance of tinned copper cables ensures a stable power supply to critical IT infrastructure, reducing the risk of downtime and data loss in the event of a power failure.

4. Installation and Maintenance Considerations

When installing and maintaining tinned copper power cables, there are several important considerations to keep in mind to ensure optimal performance and longevity:

4.1 Proper Termination: It is essential to use the correct tools and techniques to terminate tinned copper power cables effectively. The tin coating can affect the soldering process, so it is important to follow manufacturer recommendations and industry best practices when making connections to ensure a reliable electrical connection.

4.2 Environmental Factors: Tinned copper power cables are well-suited for use in harsh environments, but it is still important to protect the cables from excessive moisture, temperature extremes, and physical damage. Installing cable trays, conduit, and protective sleeves can help to safeguard tinned copper cables from environmental hazards.

4.3 Inspection and Testing: Regular inspection and testing of tinned copper power cables are essential to ensure that they are functioning correctly and are free from defects. Visual inspections, continuity tests, and insulation resistance tests can help to identify any issues early on and prevent potential failures.

4.4 Proper Handling: When handling tinned copper power cables, it is important to avoid bending or kinking the cables excessively, as this can damage the conductors and compromise their performance. Using cable guides, supports, and strain relief devices can help to maintain the integrity of tinned copper cables during installation and maintenance.

5. Conclusion

Tinned copper power cables are a versatile and reliable choice for power transmission applications across various industries. Their corrosion resistance, solderability, flexibility, and longevity make them ideal for use in demanding environments where traditional copper cables may fail. By understanding the advantages and applications of tinned copper power cables and following best practices for installation and maintenance, users can ensure the efficient and safe operation of their electrical systems.